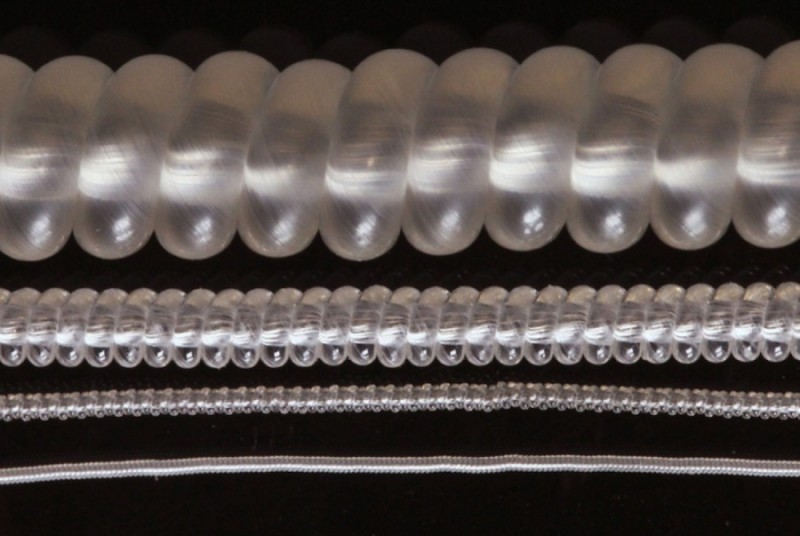

artificial muscles made by winding nylon fibers . Thickness (top to bottom): 2.45 mm, 860 microns 280 m and 150 micrometre (each microns or micrometers, equivalent to 0.001 mm). Credit: Science / AAAS

sewing thread and fishing were used in the development of artificial muscles that can support weights up to 100 times faster than human muscles of the same length and weight, says a team of scientists.

“Simplicity is the beauty of this technology,” said Ray Baughman , an expert in chemistry from the University of Texas at Dallas and leader of the study, described in the February 20 issue of the journal Science . According to Baughman own, even high school students can build the artifacts from the comfort of their homes.

Making one of these artificial muscles is a matter of hope – usually using a drill (drill) – fishing lines and sewing, composed of polymers very resistant. The result is a twist fibrous muscle capable of moving a heavy at a speed of over 10 thousand revolutions per minute rotor.

In situations of extreme twist, the fiber is wound, as can easily be checked with a snap ring. Furl fiber in the same direction of twist creates muscles that contract when exposed to heat and expand when cooled. However, if the winding and twisting directions are different, the heat causes the expansion of the muscle.

applications of the technique can cater automatic devices for opening and closing windows for controlling the temperature of a room garments and allowing better evaporation of sweat on the skin surface (by extending the fiber) to maintain the temperature body. The researchers report that, beyond these practical uses, the technology may ultimately enhance limb movement of robots, androids and mechanical exoskeletons, where the heat, which causes the effects of contraction and relaxation of the fiber, can be replaced by electrical stimulation

“The humanoid robots, exoskeletons or current prosthetic limbs are mechanically primitive,” says Baughman, since they depend on the energy provided by hydraulic motors or by causing these mechanical parts are less skilled than a human hand, by instance.

Other scientists had created artificial muscles from metal alloys that “memorize” their original format, returning to normal whenever there is a reversal of the stimulus that excites the contraction or expansion of the league. However, these materials are usually composed of nickel and titanium, can cost $ 5K per kilogram. There are also muscles made of hollow carbon fibers, called single nanotubes (single-walled nanotubes – SWNTs) wall., But again, their costs are too high

Incidentally, it was working with SWNTs that led Baughman and his students to think about the possibility of a material with a common characteristic in relation to carbon nanotubes: the majority of these fibers aligned following the extension of the line, ensuring that , run an electrical stimulus that alters the length of the fibers, those that are around you will follow the same trend, causing expansion or contraction of the line. The researchers found that plastic polymers, such as those made of nylon, also possess this particular alignment.

The results surprised. The application of heat wires contracted polymers little more than 50% (in contrast to natural muscles contract about 20%) and the heat source is extinguished, the wires return to the original length. The materials – whose prices are estimated at just over $ 5.00 – required for the formation of artificial muscles can be obtained on the shelves of stores common

.

Although fibrous artificial muscles still can not convert electrical energy into mechanical very efficiently Baughman points out that there is no other application performance as good as the muscles of the polymer coils.

Sources: Science , LiveScience

No comments:

Post a Comment