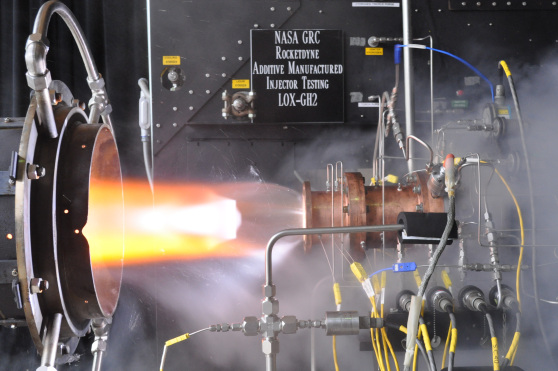

NASA has successfully tested a rocket engine in which the fuel injection system was constructed using the 3D printing. The North American Space Agency states that the use of printed pieces reduces the costs and production times.

Considered one of the most important components of the rockets, the most expensive to produce and more time consuming to build, the experience brings good news for U.S. entity. At the time of manufacture eg fuel injection system takes about a year to be built, while using 3D printing took less than four months and cost 70% less. But the question that places to start is, “and does not melt?”. The answer is no. The piece was not printed with machines that make use of plastic elements, but was built before through a technique that uses lasers to seal and compact powders of metal at high temperatures to build 3D structures.

NASA admits this test, conducted in the Research in Cleveland, USA, opens doors to new possibilities in the aerospace industry and even admits the possibility of the future “spacecraft whole” being printed.

Recently the TeK had realized other printing method 3D building metal structures and uses liquid metal at room temperature to produce the components.

Written under the new Orthographic Agreement

No comments:

Post a Comment